How AI and Robotics Will Revitalize American Manufacturing

Inspired by the industrial present—and what we can rebuild from it

American manufacturing is at an inflection point. For decades, we've witnessed factories shuttering, once-thriving industrial towns shrinking, and a narrative that America "just doesn't make things anymore."

Yet quietly—and increasingly loudly—something remarkable is starting to happen: a resurgence driven by artificial intelligence (AI) and advanced robotics. This isn't about recreating the past; it's about building something entirely new, dynamic, and sustainable.

The Perfect Storm for American Manufacturing's Revival

Manufacturing is upstream from everything. When we cede manufacturing capability, we surrender much more than just factory jobs—we lose innovation capacity, supply chain resilience, and ultimately, economic security. The COVID pandemic brutally demonstrated what happens when critical production moves entirely offshore.

Three forces are now converging to create the conditions for a manufacturing renaissance:

Labor economics have fundamentally changed. The floor for manual assembly work in the U.S. is now $20-30 per hour (set by employers like Amazon). This wage floor combined with persistent labor shortages makes pure labor arbitrage increasingly unattractive.

AI has dramatically expanded what robots can do. Traditional automation excelled at repetitive, predictable tasks. Today's AI-enhanced robots can adapt to unstructured environments, handle complex materials, and even learn new tasks through demonstration.

Geopolitical tensions and supply chain vulnerabilities are forcing companies to rethink globalized production models centered around China.

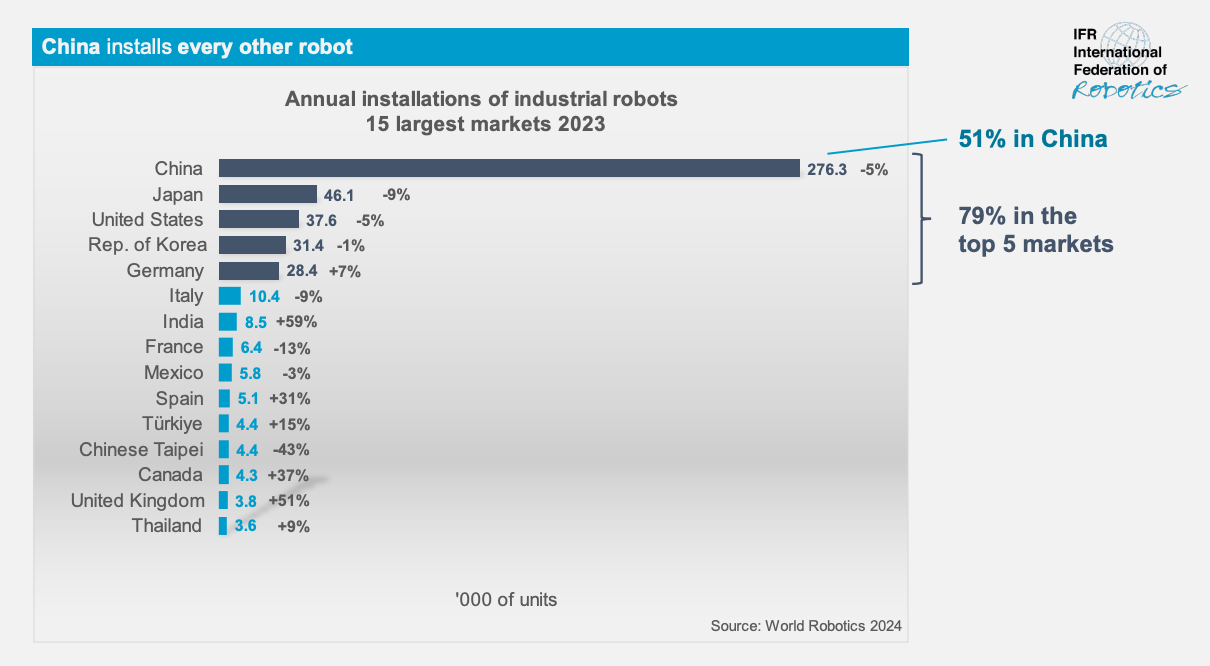

According to the preliminary results from the International Federation of Robotics (IFR), American companies are already responding to these pressures.

Total installations of industrial robots rose by 12% in 2023, reaching 44,303 units. The automotive industry led adoption with a record 14,678 robots installed, while the electrical and electronics sector saw installations rise by 37% to 5,120 units.

Beyond Automation: The AI Leap Forward

Previous waves of automation focused on replacing humans at specific repetitive tasks. The fundamental limitation was that robots needed structured environments and explicit programming for every scenario they might encounter.

The technology that’s going to drastically change manufacturing is AI-enhanced robotics. These aren't robots merely programmed for repetitive tasks; they’re systems capable of learning, adapting, and improvising in real time.

The real magic here is generalization—robots learning general capabilities instead of specific, rigid instructions. Automation is going to expand to include systems equipped with:

Adaptive manufacturing: Robots that can handle variability in materials and products

Few-shot learning: Systems that can learn new tasks after seeing them performed just a few times

Error recovery: Intelligent systems that can detect when something goes wrong and correct course

This flexibility enables robots to handle complex, unpredictable tasks such as assembling electronics or delicately managing variable products like clothing. AI-driven predictive maintenance systems can identify when machinery needs service before it fails, reducing downtime and extending equipment lifespans.

The result? American factories can finally compete on precision, quality, and adaptability rather than merely on cost-cutting.

Reinventing the Small and Medium Manufacturer

Historically, advanced robotics were exclusive to high-end mass production environments. But falling costs, modular systems, and accessible robotics-as-a-service models have opened doors for small and medium-sized factories. These smaller players can now leverage sophisticated robotics for efficiency, scale, and precision previously reserved for industrial giants.

The math is compelling:

The average price of industrial robots has halved from around $47,000 in 2011 to $23,000 in 2022.

According to ARK Invest, costs are projected to fall another 50-60% by 2025

While automation requires significant upfront investment, the long-term operational economics increasingly favor domestic production

This democratization of robotics is critical because small factories form the backbone of America's manufacturing base. By empowering them with AI-driven robotics, we’re not just preserving existing businesses—we're potentially igniting a manufacturing renaissance in overlooked communities nationwide.

Economic and Strategic Imperatives

The strategic imperative is clear: global competitors, notably China, are investing aggressively in robotics and automation. America risks losing further ground without significant investments in similar capabilities.

Robotics-driven manufacturing is no longer optional; it's essential for reshoring production and maintaining economic resilience.

With ample support and investment, AI and robotics are uniquely positioned to address several critical challenges that American manufacturing faces:

1) The Persistent Labor Gap

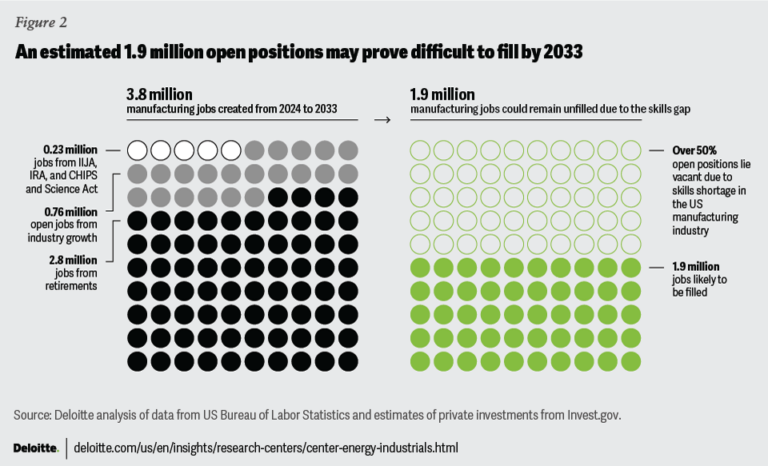

According to the U.S. Chamber of Commerce, there are currently over 500,000 open manufacturing jobs in the U.S., and research from Deloitte expects that shortage to rise to 1.9 million jobs by 2033 if manufacturers are unable to address the skills and applicant gaps. This combination of retiring laborers and increased demand for domestic supply chains is creating an unsustainable pressure on production capacity.

The labor shortage creates a cascade of problems: high turnover rates (36.6% in 2023), increased training costs, quality inconsistencies, and rising labor costs. Automation targets precisely these issues by reducing dependency on hard-to-fill positions while creating new technical roles with better pay and working conditions.

2) Operational Efficiency Constraints

American manufacturers struggle with significant capacity limitations and operational inefficiencies that restrict productivity and competitiveness. Traditional production models are constrained by human work patterns, shift changes, and downtime for maintenance and reconfiguration.

AI-enhanced robotics transforms this equation by enabling continuous operation, minimizing downtime, and maximizing equipment utilization. These systems can work around the clock, dramatically increasing throughput from the same physical footprint while amortizing fixed costs across greater output. The result is not just higher production volumes but lower per-unit costs that can compete with overseas manufacturing.

3) Global Competitive Disadvantage

America's robot adoption is frankly abysmal. Reports indicate that just 20% of US factories between 50 and 150 employees have a robot, half the rate of those with more than 1,000 staff. Meanwhile, China’s installed more than 50% of new robots globally in 2023. This automation gap translates directly into productivity and cost disadvantages.

The trade deficit in advanced technology products has been accelerating at an alarming rate, growing from $187 billion in 2020 to $298 billion in 2024. In 2021, the United States accounted for 78 percent of the total trade deficit among industrial nations, while China accounted for 45 percent of the total trade surplus.

The Path Forward

For too long, America has focused on inventing new technologies while letting others master the art of production at scale. This bifurcation has hollowed out our manufacturing base and created dangerous dependencies.

As researcher Jonas Nahm observed, "In the United States firms have typically taken the form of start-ups with skills in the invention of new technologies, but with far fewer capabilities in the commercialization and production of these inventions." By contrast, China pursued what he terms "innovative manufacturing" focused on "the R&D required for scaling and commercializing novel technologies."

To rebuild American manufacturing, we need a three-pronged approach:

Technology deployment: Accelerate the adoption of AI-enhanced robotics across all levels of manufacturing, from automotive giants to small machine shops

Workforce development: Create training programs that equip workers with the skills needed to operate, maintain, and optimize these new systems

Innovation ecosystems: Build regional "robot hubs" that concentrate expertise, suppliers, and support services

The revitalization of American manufacturing hinges on adopting AI-powered robotics widely and intelligently. It requires strategic investments in training, data infrastructure, and supportive policies designed to nurture this technological evolution.

The technologies are here. The economic case is compelling. The geopolitical imperative is clear. What's needed now is the will to invest, adapt, and build.

Done right, the outcome won't simply be a stronger manufacturing sector—it will be a more resilient economy, better-paying and more satisfying jobs, and a renewed sense of manufacturing pride. AI and robotics represent not just a technological leap but a cultural shift—a decisive move toward a smarter, more prosperous future for American industry.

This piece captures the transformative potential of AI and robotics in reshaping the manufacturing landscape. At IntelliSell, we’re observing firsthand how intelligent automation is not only enhancing productivity but also enabling more agile and resilient supply chains.

The integration of AI-driven robotics facilitates real-time decision-making, predictive maintenance, and adaptive production processes. These advancements are critical for manufacturers aiming to meet the demands of a rapidly evolving market while maintaining efficiency and quality.

Moreover, the shift towards smart factories underscores the importance of upskilling the workforce to collaborate effectively with advanced technologies. Investing in human capital is essential to fully realize the benefits of this industrial evolution.

Thank you for highlighting these pivotal developments that are steering the future of manufacturing.

—IntelliSell Team

Transforming market noise into strategic intelligence for manufacturers